Solutions for the

Textile Industry

The textile industry is one of the oldest and most diverse industrial sectors worldwide. From spinning and weaving to the highly automated production of technical fabrics, modern textile machines operate with utmost precision and speed. Reliable drive components such as safety and shaft couplings are essential in this context. They protect machines from overload, ensure precise torque transmission, and play a key role in the safety and efficiency of the systems. In an industry that operates around the clock, durable and low-maintenance coupling solutions are a crucial factor for production reliability.

Matching products

Torque limiters for direct drives

0.3 - 23000 Nm

Torque limiters for direct drives protect against overload in the motor train and ensure precise torque transmission. They are used throughout plant, machine and test bench construction. While the variants with metal bellows mounting primarily compensate for axial, radial and angular misalignments, the torque limiters with elastomer mounting primarily have an electrically insulating and vibration-damping effect. Both types of coupling provide effective and purely mechanical protection against overloads and the resulting machine downtimes.

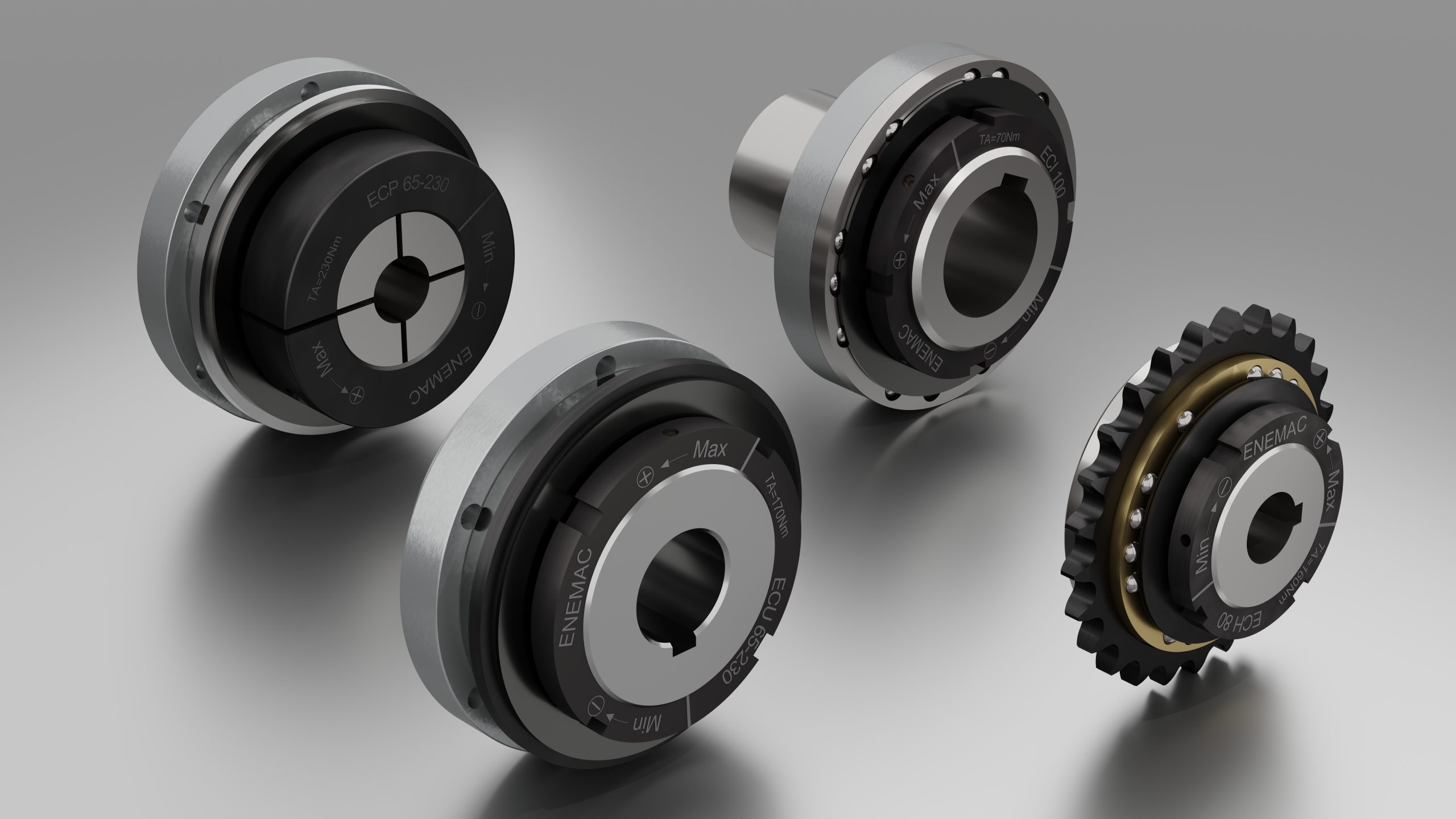

Torque limiters for indirect drives

0.3 - 23000 Nm

Torque limiters for indirect drives are indispensable components for torque transmission in the motor train of a wide range of industrial applications for attachment to output elements such as pulleys, sprockets or toothed pulleys. They are used, for example, in textile and packaging machines as well as in can, cup and beverage filling machines. They provide effective and purely mechanical protection against overloads and the resulting machine downtimes.

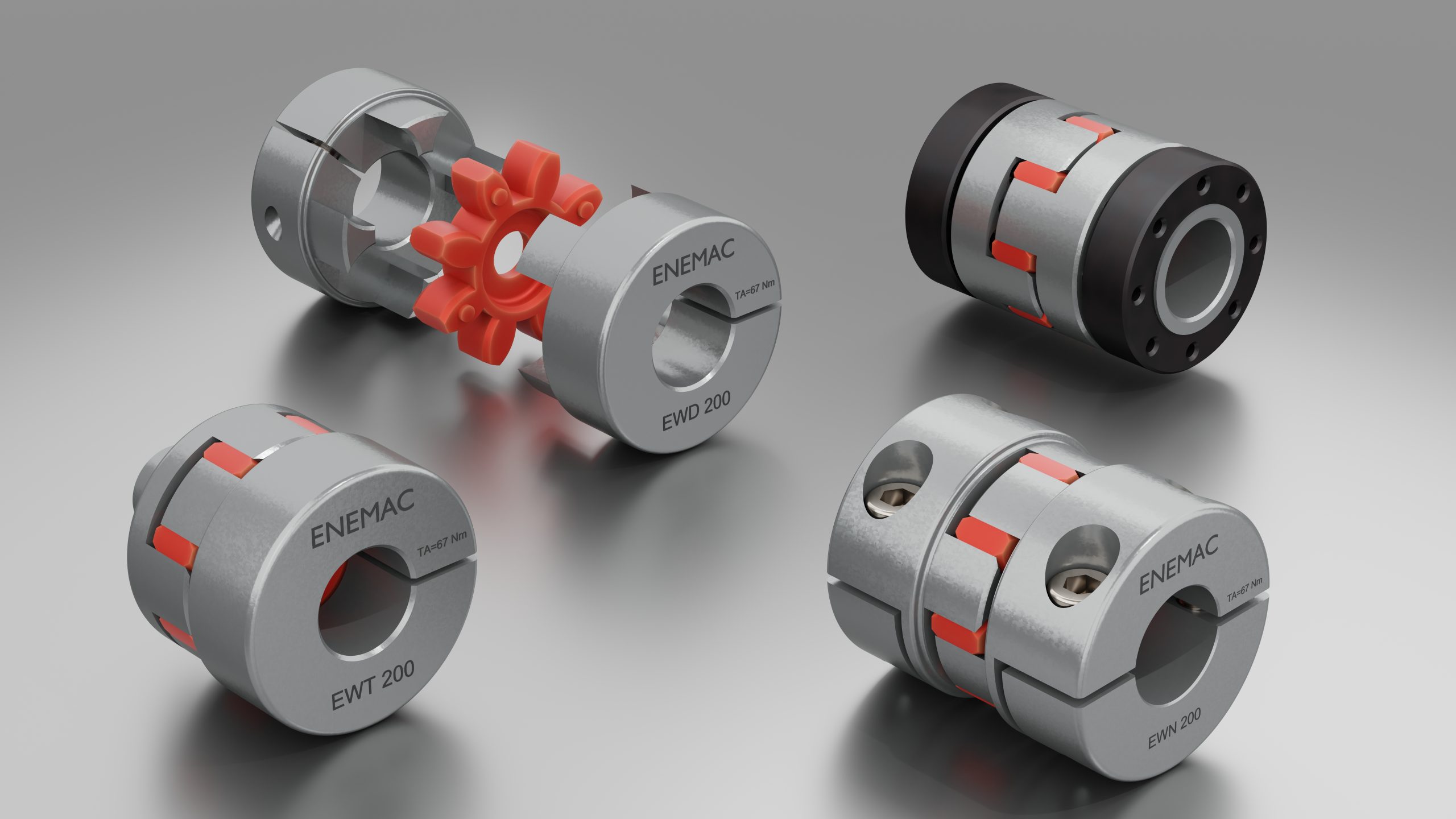

Elastomer couplings

0.7 - 2000 Nm

Elastomer couplings (claw couplings) are plug-in equalising couplings for backlash-free, angularly accurate transmission of torques in direct drives. The polyurethane insert, available in different Shore hardnesses, has a vibration-damping and electrically insulating effect.

Metal bellows couplings

0.4 - 6000 Nm

Metal bellows couplings compensate for axial, radial and angular shaft misalignment, are quick and easy to install and ensure reliable torque transmission at speeds of up to 95,000 rpm. They can be installed at operating temperatures of up to 350°C. Stainless steel versions are available for demanding applications.

Whether you need customized coupling solutions or expert advice - we are here for you. Contact us today and benefit from our expertise.

Product compass

Find the perfect coupling - fast and easy!

Our product compass will help you to find the right safety coupling or shaft coupling for your application. Relevant selection criteria such as nominal torque, bore diameter, shaft connection or desired compensation element make the product search easier. You can download further technical information such as dimensional drawings and CADs or send us a specified inquiry directly via a list of results configured for you under “Details”. We look forward to your visit!