ENEMAC - Precision in drive technology since 1981

Welcome to ENEMAC Gesellschaft für Energie- und Maschinentechnik mbH, your experienced partner for high-precision drive components. Since its foundation in Kleinwallstadt, Germany in 1981, ENEMAC has stood for innovation, quality, and reliability in drive technology. As a manufacturer and distributor, we offer a comprehensive range of high-quality couplings for demanding industrial applications:

Torque Limiters (Safety Couplings): reliably protect motor drives in torque ranges from 0.3 Nm to 23,000 Nm against overload, thus minimizing downtime. They are used in packaging and filling systems in the food and beverage industry, the pharmaceutical industry, in mechanical and plant engineering, in test bench construction, in conveyor systems, and in the fields of automation and robotics, among others.

Shaft Couplings: are precision compensating couplings for backlash-free transmission of torques from 0.4 Nm to 65,000 Nm. Depending on the type, they can be used at speeds of up to 95,000 rpm and operating temperatures of up to 350 °C. Thanks to their versatility, they are ideal for a wide variety of shaft-hub connections. The product portfolio includes: metal bellows couplings, elastomer couplings, and multi-disc couplings. Shaft couplings are used in all areas of mechanical and plant engineering, from precision production facilities to complex test systems.

Stainless Steel Couplings in Hygienic Design: comply with the strict hygiene regulations of the food and pharmaceutical industries and are also suitable for use in medical technology and clean rooms. We use only high-quality A2 and A4 stainless steels for the manufacture of safety couplings, shaft couplings, and spacer couplings in hygienic design to ensure the highest quality and durability in demanding environments.

Your partner for reliable drive solutions – ENEMAC supplies precise, durable, and versatile coupling solutions that operate your machines and systems efficiently, safely, and economically. Discover our comprehensive product portfolio and experience Made in Germany quality for every industrial application.

Product compass

The ENEMAC product compass (product finder) helps you to easily find the right torque limiter or shaft coupling for your application. Relevant selection criteria such as nominal torque, bore diameter, shaft connection or required compensation element make it easier to find the right product. You can download further technical information such as dimensional drawings and CADs via a list of results configured for you under ‘details’ or send us a specified enquiry directly. We look forward to your visit!

Products

Torque limiters

Mechanical overload protection to minimise costly repairs and machine downtime

ENEMAC safety couplings, also known as torque limiters, are mechanical components that actively protect drives from overload. They prevent malfunctions—such as blockages or foreign objects—from causing damage to gearboxes, motors, or downstream drive components. At the same time, they ensure backlash-free torque transmission, compensate for misalignment, and, depending on the coupling type, can also dampen vibrations.

Today's automated production lines must operate continuously with maximum process stability. Every unplanned downtime causes costs – especially in industries with high plant availability and cycle-critical processes. Safety couplings separate the drive and output sides within milliseconds when a predefined torque is exceeded. To do this, a spring presses balls into calottes in a form-fitting manner. If the set limit torque is exceeded, the balls overcome the spring force and the connection is released. Power transmission stops immediately and rotating masses run freely. Once the fault has been rectified, the elements automatically re-engage – with ENEMAC, this is achieved with precise 360° synchronous engagement. The purely mechanical mode of operation ensures maximum operational reliability, even in the event of power failures or control errors and effectively protects drives and gearboxes from consequential damage.

ENEMAC safety couplings for direct or indirect drives reliably secure torques from 0.3 Nm to 23,000 Nm and can be used at temperatures ranging from a minimum of -30 °C to a maximum of 200 °C. The shaft connection is made by means of clamping hubs, keyways, or conical bushings.

Safety couplings protect drives in filling and packaging systems in the food and beverage industry, in general mechanical and plant engineering, in special machine construction, in test benches, and in the process industry.

Shaft couplings

Compensating couplings for precise and backlash-free torque transmission from drive shaft to output shaft

ENEMAC shaft couplings are backlash-free compensating couplings for the precise, angle-accurate transmission of torques from 0.4 Nm to 65,000 Nm. Depending on the series, they can be used at speeds of up to 57,000 rpm and temperatures of up to 350°C. Thanks to the wide variety of designs, ENEMAC offers the technically appropriate coupling design for almost every machine – from high-precision axes in machine tool construction to automation, packaging technology, measurement and testing technology, pump systems, energy systems, steel and hot operating applications.

Metal bellows couplings from ENEMAC are completely backlash-free, have high torsional stiffness, extremely low restoring forces, and are therefore particularly suitable for precise positioning tasks and high-load changes in direction of rotation. They enable uniform and controllable power transmission.

Elastomer couplings dampen vibrations and shocks and can effectively prevent resonance from reaching the drive. They are electrically insulating and can be precisely adapted to the required machine characteristics using different Shore hardnesses. They are economical to use, robust, and easy to install.

Disc couplings transmit high torques in a compact design, offer high torsional stiffness, are maintenance-free, extremely durable, and ideal for heavy-duty applications in mining and foundries.

Since 1981, ENEMAC has stood for technical coupling solutions with high operational reliability, long service life, and absolutely reliable repeatability. Every designer thus receives a solution that is precisely tailored to the actual load and technically sound—no compromise.

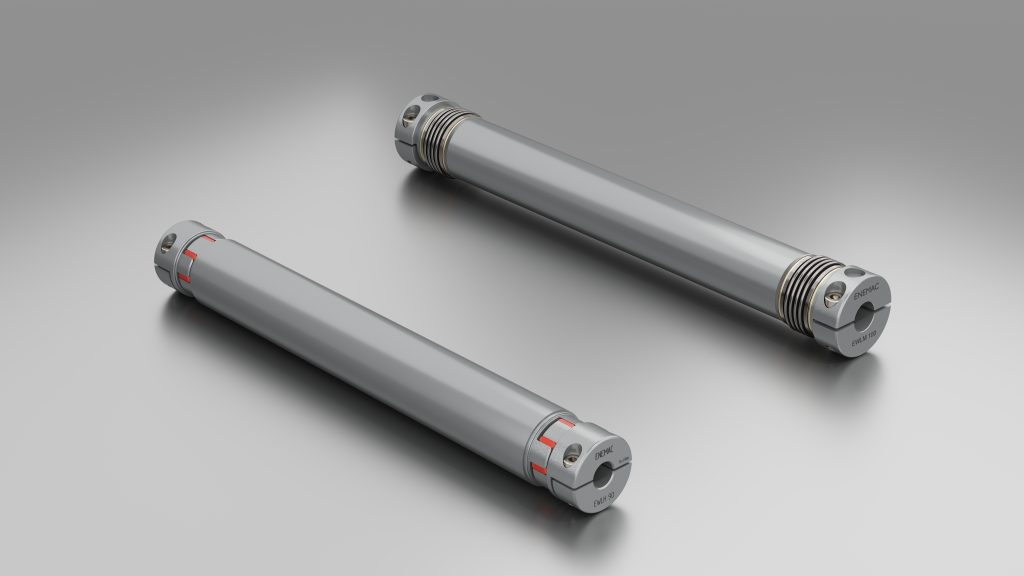

Distance couplings

Compensating couplings for bridging large centre distances

ENEMAC distance couplings are shaft couplings for bridging large centre distances and compensating for shaft misalignment. Distances of up to 6 m can be bridged using variable-length intermediate tubes made of high-strength aluminium, which are adapted to customer requirements. ENEMAC spacer couplings can be used as backlash-free connecting, cardan or synchronising shafts at temperatures of up to 300 °C and cover a torque range of 10 Nm - 1,600 Nm.

Stainless steel couplings

Torque limiters and shaft couplings made of stainless steel in hygienic design

ENEMAC stainless steel couplings comply with the strict hygiene regulations of the food and pharmaceutical industries and can also be used in the field of medical technology and in clean rooms. Stainless steels A2 and A4 are used in the manufacture of torque limiters, shaft couplings and spacer couplings in hygienic design, guaranteeing the highest quality for demanding applications.

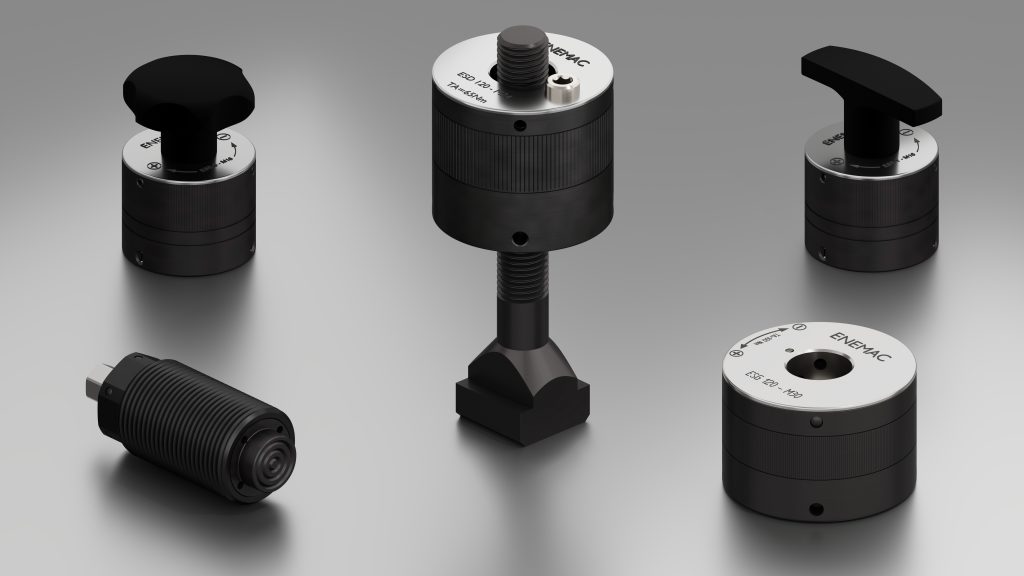

Clamping technology

Force-enhanced clamping of tool and workpiece.

ENEMAC clamping technology guarantees safe and force-enhanced clamping of tools and workpieces with a nominal clamping force of up to 350 kN. With various force amplifier systems and hydromechanical spring clamping systems, ENEMAC clamping technology increases both operational safety and efficiency in your production and also shortens set-up and production times. ENEMAC clamping elements can be used as original equipment in machines or retrofitted.

Contact

Our customers

Our products are as diverse as their applications. We would like to present a selection of our customers and thus give you an insight into the numerous possible applications:

As an internationally active manufacturer of filling and packaging systems for the beverage, food and non-food industries, KHS GmbH occupies a leading position in the sector. KHS develops and manufactures the entire portfolio of filling and packaging machines at five German sites and additional production facilities in Brazil, the USA, Mexico and India. In line with its corporate responsibility, KHS GmbH places particular emphasis on the development of sustainable solutions, environmentally friendly production and social aspects.

IWK Verpackungstechnik GmbH focuses on the efficient, precise and attractive packaging of goods from the pharmaceutical and cosmetics sectors. Good ideas combined with the company's pioneering spirit have given IWK a strong global presence. IWK currently holds a considerable number of patents for key technologies and invests significantly more in research and development each year than the industry average. This results in numerous innovations every year. IWK has 2 production sites in Europe and Asia and currently employs around 450 people, most of them at its headquarters in Stutensee, Baden-Württemberg.

KOLBUS offers the world's most comprehensive product range of bookbinding machines. It consists of over 30 machine types covering all areas of application for the production of bound products from the folded sheet onwards (including collating, perfect binding, separating and three-knife trimming, book cover production and finishing, book end production, feeding, stacking and transporting). Inline production systems for the production of magazines, catalogs, paperbacks and hardcover books are a KOLBUS specialty. Around the globe, KOLBUS production systems enable daily profits and new opportunities in the various product segments - accompanied by reliability and a consistent focus on quality.

NIKO Nahrungsmittel-Maschinen GmbH & Co. KG was founded in 1976 and has since developed into a reliable specialist for machines and systems for the food and beverage industry. The design of the machines and systems is based on the current, valid machine guidelines and is oriented towards the principles and requirements of the food industry (IFS, HACCP, ISO and CE certification). Our systems are characterized by high production efficiency, easy cleaning and maintenance and low maintenance costs. NIKO realizes machines for the following industries: Canned food industry, delicatessen industry, beverage industry, confectionery industry and snack industry.