Solutions for

Special Machine Construction

Special machinery construction develops customised machines and systems that are specifically tailored to customer-specific production requirements. Whether in automation, packaging, filling or quality assurance - maximum precision, efficiency and flexibility are required. Technical components must be robust, durable and adaptable, especially in sensitive areas such as the pharmaceutical and food industries. Materials such as stainless steel in hygienic design and safe drive systems with torque limitation and overload protection ensure trouble-free processes. Customised machines enable economical and safe production, precisely tailored to the individual requirements of each industry.

Matching products

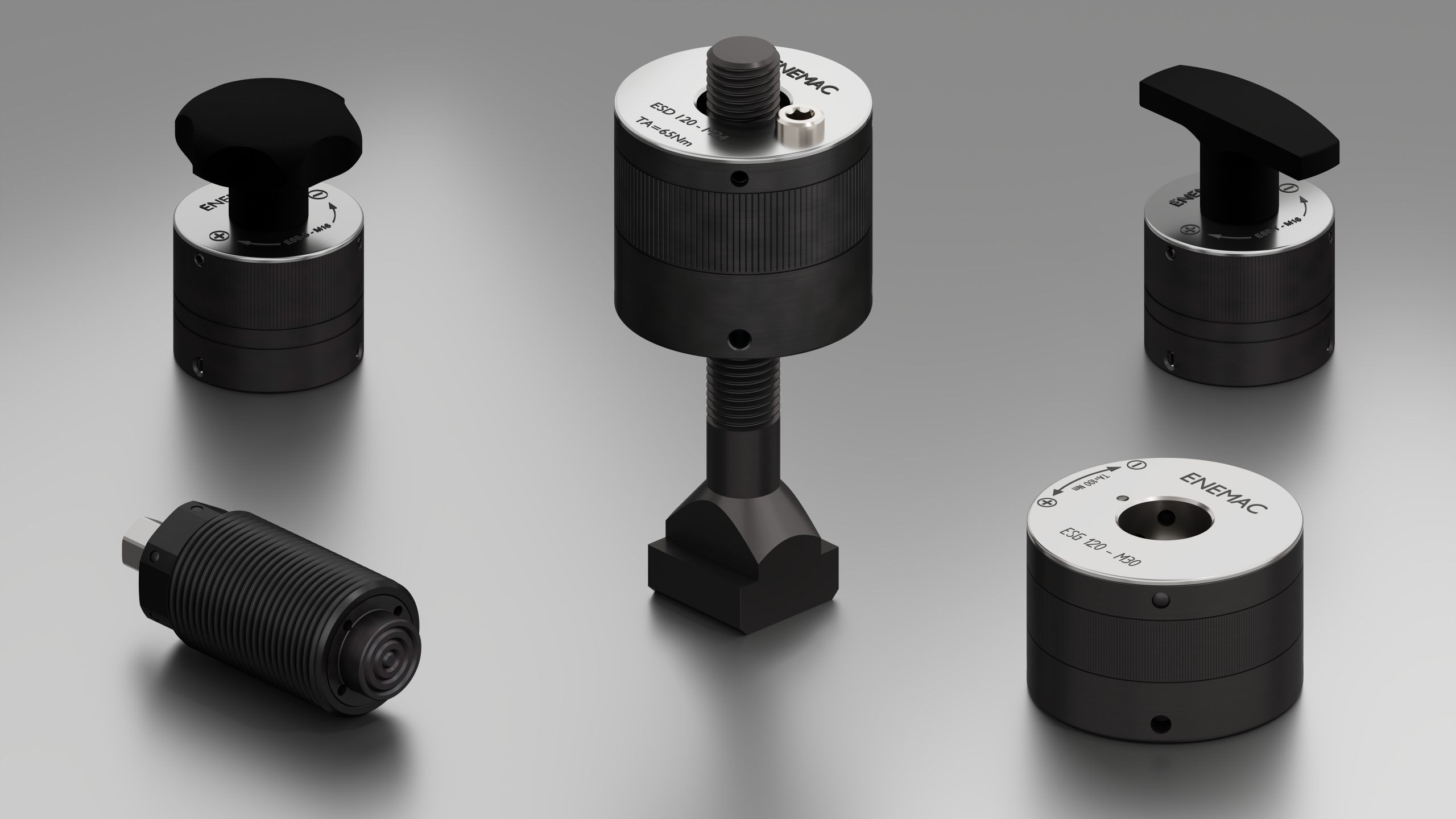

Clamping technology

40 - 250 Nm

Clamping technology guarantees safe and force-enhanced clamping of tools and workpieces with a nominal clamping force of up to 350 kN. With various force amplifier systems, ENEMAC clamping technology increases both operational safety and efficiency in your production and also shortens set-up and production times. ENEMAC clamping elements can be used as original equipment in machines or retrofitted.

Torque limiters for direct drives

0.3 - 23000 Nm

Torque limiters for direct drives protect against overload in the motor train and ensure precise torque transmission. They are used throughout plant, machine and test bench construction. While the variants with metal bellows mounting primarily compensate for axial, radial and angular misalignments, the torque limiters with elastomer mounting primarily have an electrically insulating and vibration-damping effect. Both types of coupling provide effective and purely mechanical protection against overloads and the resulting machine downtimes.

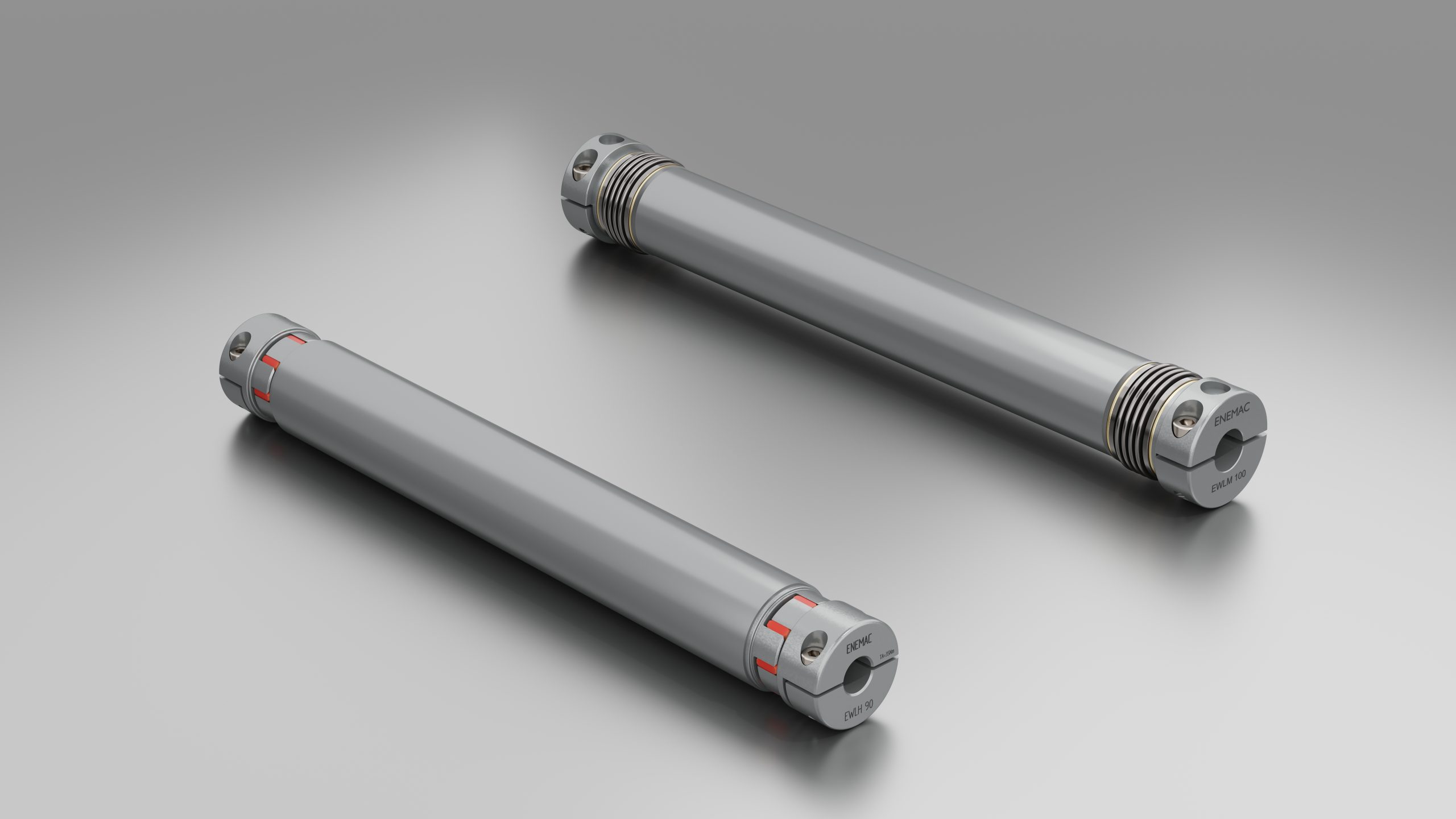

Distance couplings

10 - 1600 Nm

Distance couplings are shaft couplings for bridging large centre distances and compensating for shaft misalignment. Distances of up to 6 m can be bridged using variable-length intermediate tubes made of high-strength aluminium, which are adapted to customer requirements. ENEMAC spacer couplings can be used as backlash-free connecting, cardan or synchronising shafts at temperatures of up to 300 °C and cover a torque range of 10 Nm - 1,600 Nm.

Whether you need customized coupling solutions or expert advice - we are here for you. Contact us today and benefit from our expertise.

Product compass

Find the perfect coupling - fast and easy!

Our product compass will help you to find the right safety coupling or shaft coupling for your application. Relevant selection criteria such as nominal torque, bore diameter, shaft connection or desired compensation element make the product search easier. You can download further technical information such as dimensional drawings and CADs or send us a specified inquiry directly via a list of results configured for you under “Details”. We look forward to your visit!